Plastic Bottle Recycling Line

Plastic Bottle Recycling Line

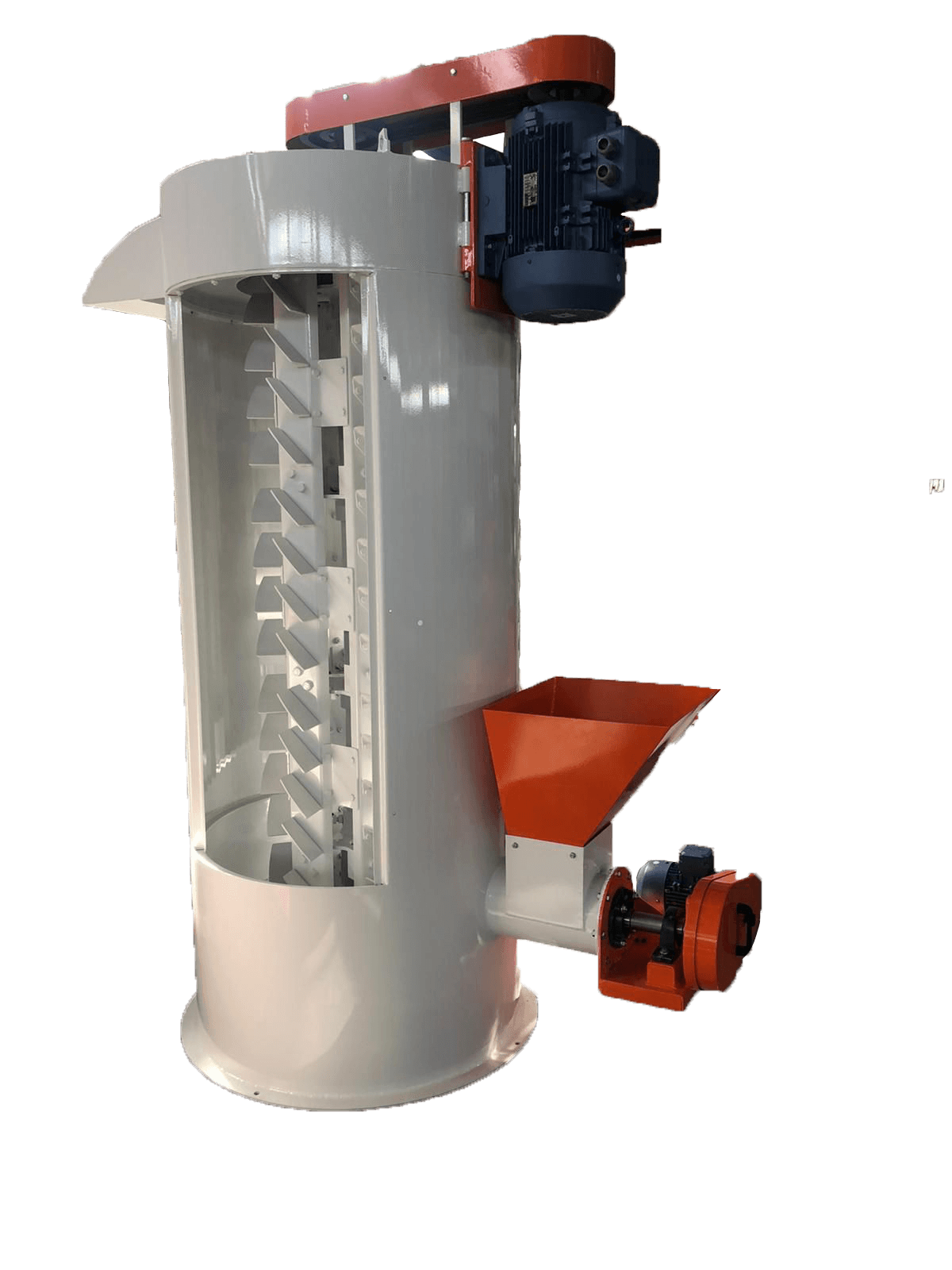

INOTEK's Plastic Bottle Recycling Line is a state-of-the-art solution designed to transform used plastic bottles into high-quality recycled materials.

Combining advanced technology, efficiency, and sustainability, our recycling line is perfect for businesses looking to reduce waste, lower costs, and contribute to a circular economy.

Whether you're a small-scale recycler or a large industrial facility, our system is tailored to meet your needs.

COMPACT RECYCLING LINE:

Compact and Modular Design: Perfect for small to medium-sized recycling

operations with limited space.

Quick Installation: Easy to set up and integrate into existing

facilities.

Cost-Effective: Lower initial investment and operational costs, ideal

for startups or smaller businesses.

High-Quality Output: Produces clean, high-quality PET or HDPE flakes

suitable for reuse in various industries.

Energy-Efficient: Designed to minimize energy consumption while

maintaining high productivity.

Portable Options: Some models are semi-mobile, allowing for flexibility

in operation locations.

User-Friendly: Simple controls and minimal maintenance requirements.

Scalable: Can be expanded as your business grows.

INDUSTRIAL RECYCLING LINE:

High Capacity: Designed for large-scale recycling operations,

handling up to 5 tons/hr.

Advanced Sorting Technology:

Utilizes AI, NIR

(Near-Infrared) scanners, and optical

sorters for precise material separation.

Fully Automated: Reduces labor costs and increases efficiency with

automated feeding, sorting, and processing.

Comprehensive Washing System: Multi-stage washing units ensure the highest purity

of recycled flakes.

Durable Construction: Built to withstand heavy-duty use, ensuring long-term

reliability.

Pelletizing Option: Includes an integrated pelletizer for producing

high-quality plastic pellets.

Water Recycling System: Closed-loop water treatment minimizes water usage and

environmental impact.

Customizable: Can be tailored to specific material types (PET,

HDPE) and output requirements.

KEY FEATURES:

Efficient Sorting: Advanced sorting systems ensure high-purity output by

separating plastics by type and color.

High-Quality Washing: Multi-stage washing removes contaminants, labels, and

adhesives.

Energy Efficiency: Designed to reduce energy consumption and operational

costs.

Durability: Robust construction ensures long-lasting performance

even in demanding environments.

Sustainability: Supports circular economy goals by transforming waste

into reusable materials.

Automation: Reduces manual labor and increases throughput with

automated processes.

APPLICATIONS:

Textile Industry: Recycled PET flakes are used to produce polyester

fibers for clothing and fabrics.

Packaging: Recycled HDPE and PET are used to manufacture new

bottles, containers, and packaging materials.

Construction: Recycled plastics are used in plastic lumber, pipes,

and other building materials.

Automotive: Recycled plastics are used in car parts, dashboards,

and interior components.

TECHNICAL SPECIFICATIONS:

| Parameter | Compact Line | Industrial Line |

|---|---|---|

| Capacity | 500 kg/hr - 1 ton/hr | 1 ton/hr - 5 tons/hr |

| Power Consumption | 50 kW - 100 kW | 200 kW - 500 kW |

| Output | Flakes (5-12 mm) | Flakes or Pellets |

| Automation Level | Semi-Automated | Fully Automated |

| Water Usage | 2 m³/hr | Water Usage 2 m³/hr 5 m³/hr (with recycling) |

| Noise Level | <75 dB | <80 dB |

| Dimensions | 10m x 5m x 3m | 20m x 10m x 5m |

You might be interested